From initial idea to serial production

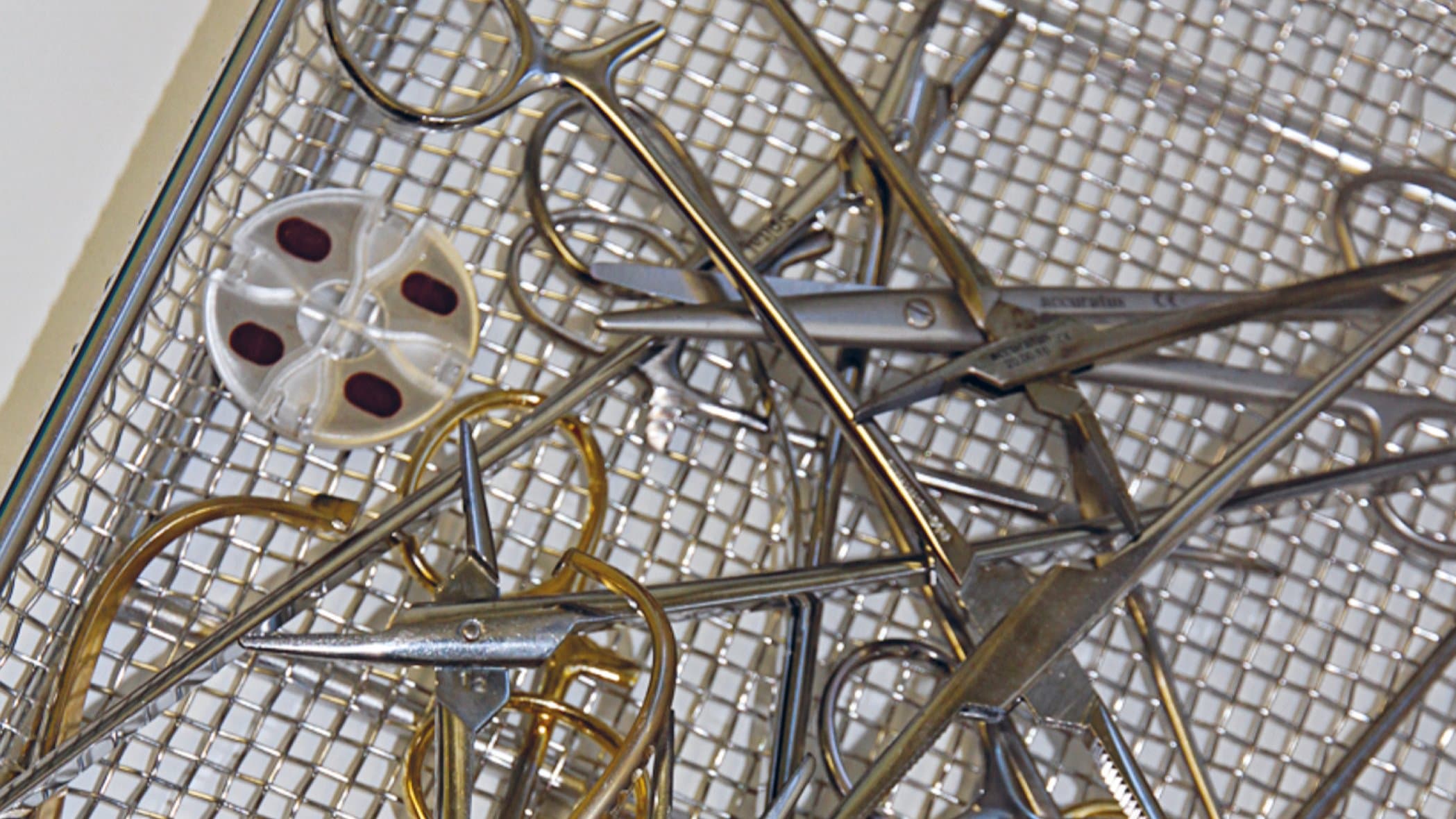

A customer wanted to eliminate design-related problems with their own product. Learn how Mythentec developed a functional indicator that shows in the simplest way the cleaning effect of dishwashers for contaminated surgical instruments.

Initial Situation

As the customer wished to eliminate critical, design-related problems with standard indicators and to introduce its own improved product, they commissioned Mythentec to develop a functional indicator optimized in terms of its informative value. A prerequisite was the product’s compliance with the EN ISO 15883 standard for washer-disinfectors.

Development

Work at Mythentec ranged from the development of an optimized design right through to series production, resulting in a solution that achieves clear, unequivocal information on cleaning quality. Mythentec presented a complete concept in less than 60 development hours, which encompassed a technical specification, 3D design, material selection, and prototypes. All other suppliers (e.g. for punched parts or packaging) were evaluated and commissioned by Mythentec.

Injection Molding

The transparent cover plate was manufactured in a 4-cavity mold using medical grade polycarbonate. The molding has four snap fasteners and flights that define the four-chamber heights of the indicator ranging from 0.75 to 2 mm. Regular component inspection is realized through IPC (in-process control), with the central master computer system continually archiving actual parameters.

Further Processing

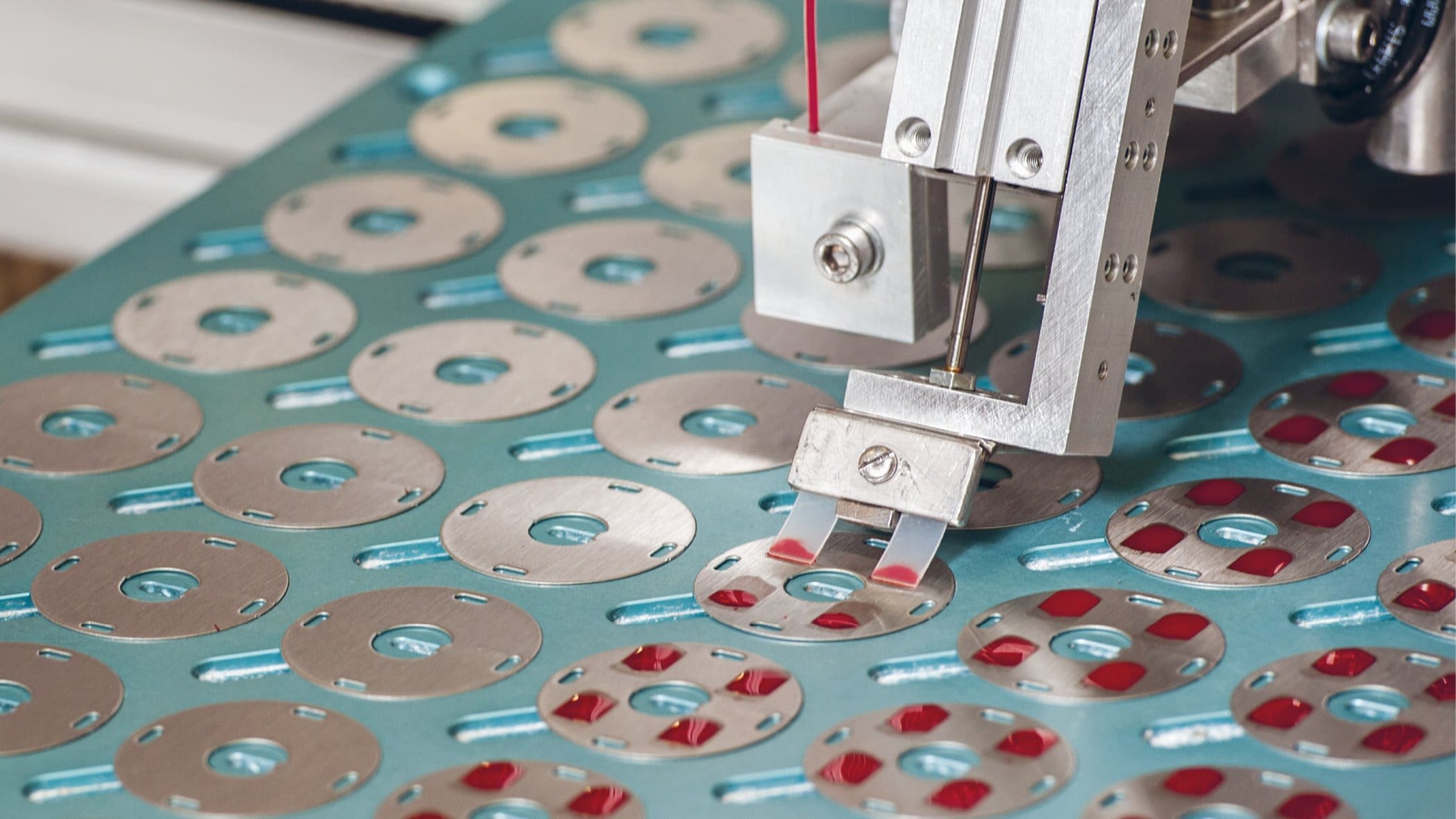

Mythentec supplies the unit ready for sale and, because of the direct procurement of all purchased parts, is the central contact for the customer. Each manufacturing step is carried out on the company’s site and must meet enhanced hygienic requirements. Sheep blood is applied to the carrier plates in a machine prior to the assembly of the plastic components. The

finished indicators are individually packaged, sealed air-tight and placed in sales boxes. The exact batches involved in all packaging units can be traced accurately through the labels.

Key Factors

- One central contact for the customer

- Direct procurement of all purchased parts

- Blood application, assembly, and packaging governed by enhanced hygienic requirements

- Automated blood application

- Complete batch traceability for all articles