Rapid optimisation and industrialisation

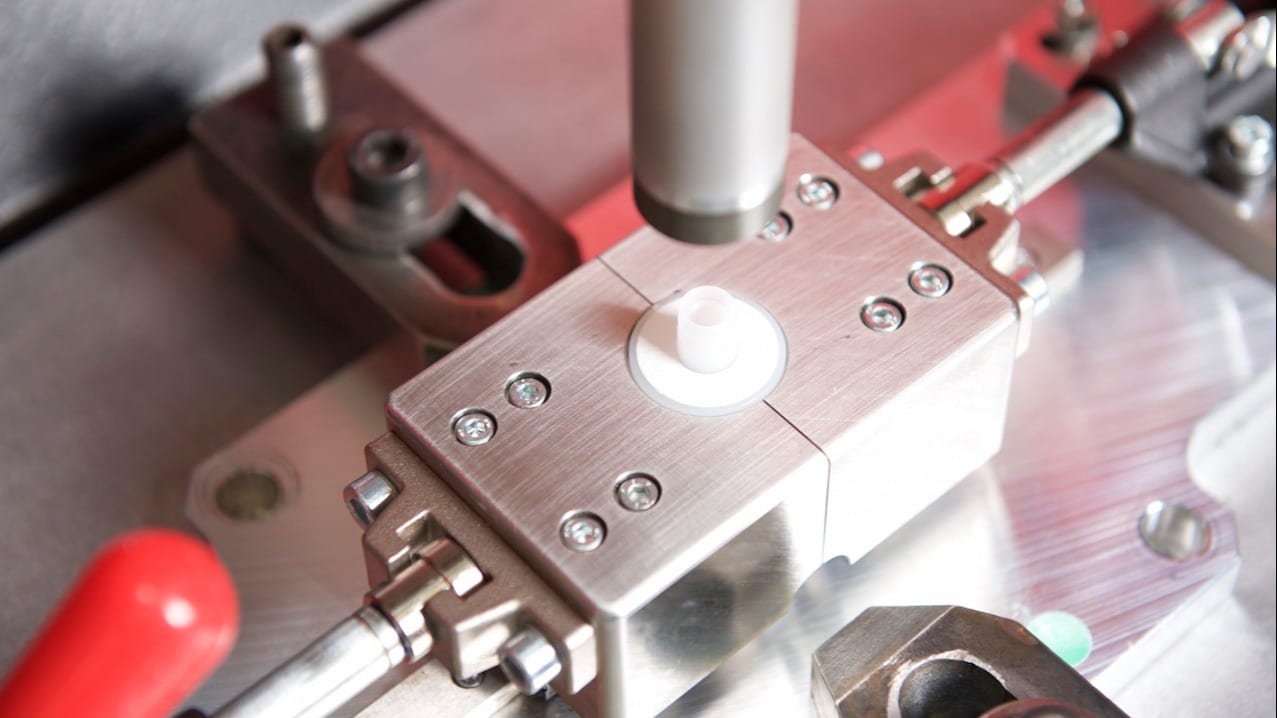

Cultivation of different cells in a fully automated module is made possible through a specially developed and patented closure for cell culture bottles. Mythentec optimized the product for the production and made a fast industrialisation possible.

Initial situation

Mythentec was involved in the development of new functionalities in the

closure required for automation and revised the 3D data to ensure its suitability

for plastic. Moreover, there was also a demand for industrialisation of all plastic parts and downstream processes in minimum time.

Development

Re-engineering of all plastic parts in accordance with requirements and in

close cooperation with the customer was successfully achieved in only one

week. Development and integration of additional functions allowed the

pre-assembly of a module and elimination of silicone seals. As a consequence,

Mythentec also created the conditions for a simplified and more

cost-effective production process. The required injection moulds were obtained

from a competent partner in China and were available in only eight

weeks for initial sampling.

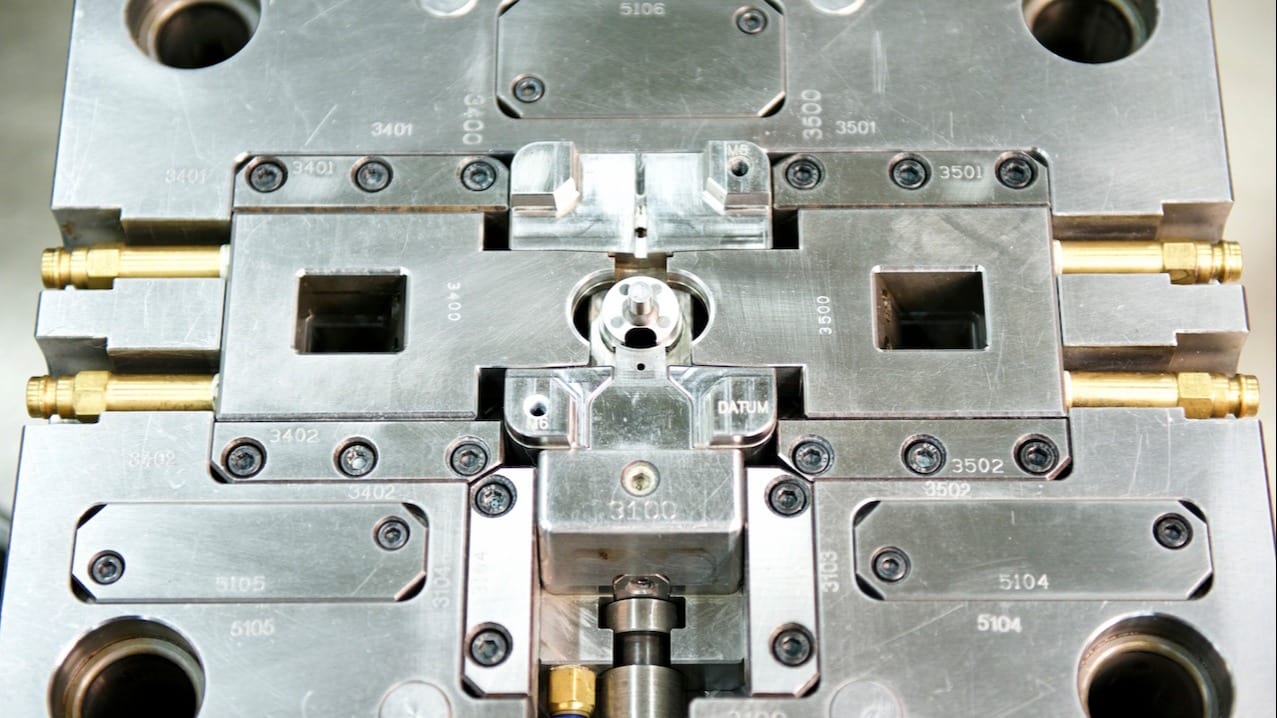

Injection moulding

Each part of this project requires a different moulding technique. Methods

employed include two-component injection, multi-slider tools with and

without conversion options for product variants, a mould with a core puller

required for a complex part geometry and a boring tool for creating the

required thread.

Further processing

Mythentec takes care of the sophisticated welding of diaphragms in filter

components with subsequent testing of the weld and airflow. The module

is then assembled in five steps and sent as a complete set for external sterilisation.

Further processing is realised under enhanced hygienic conditions,

and Mythentec guarantees consistent batch traceability.

Key factors

- One central contact for the customer

- Procurement and commissioning of tools abroad

- Industrialising of ultrasonic welding and installation

- Further processing under enhanced hygienic conditions

- Complete batch traceability for all articles