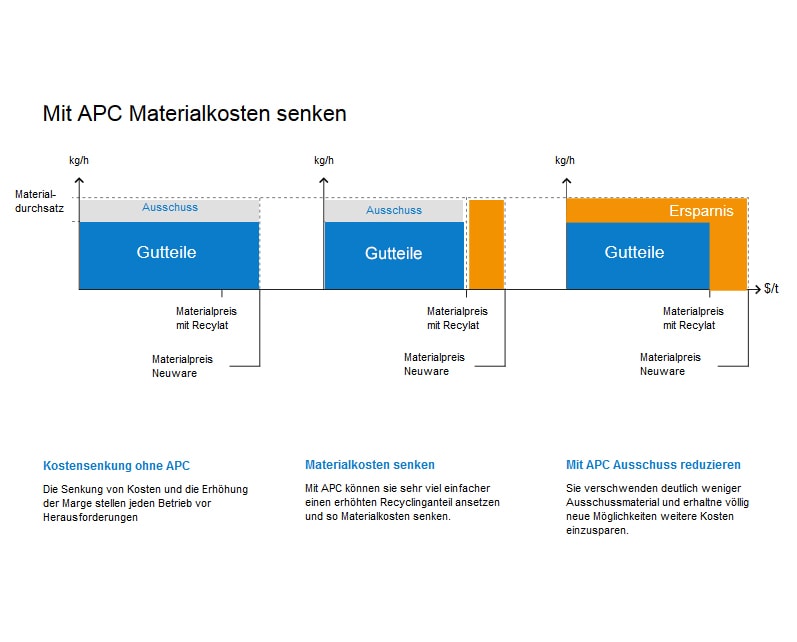

APC - Best component quality with recycled materials

Zero-defect production: The Adaptive Process Control APC machine function immediately compensates fluctuations in the injection molding process. This makes it possible to process even difficult batches and recycled materials into components that are premium quality in every respect.

NIFCO KTW GmbH, Weißenburg is a very successful mid-sized automotive supplier that specializes in high-quality interior and exterior components. Since back in 1998, the company has relied solely on KraussMaffei injection molding technology. In the meantime, 14 fully automatic machines in the clamping force range of 80 to 2300 tons have been purchased in multiple installments. This includes an MX 2300, which was equipped for manufacturing wheel house shells made from recycled materials for a German automotive supplier with the new APC (Adaptive Process Control) machine function.

Requirements:

- Using a high quantity of recycled materials without sacrificing part quality

- High-performance screw for processing the recycled material

- Transparent evaluation of the machine data

Custom solution:

- Subsequent APC installation

- HPS-AT barrier screw

- Integration of a KraussMaffei industrial robot

- Graphical analysis package

Benefits:

- Major improvement in the continuous monitoring of melt quality

- Significant reduction in reject rates

- Precise component traceability

“ We significantly reduced reject rates with the APC function.”

(Albert Burghart, Plant Manager of NIFCO KTW in Weißenburg)