Buffer system for automated part buffering

A stamping company was looking for a tailor-made solution to make its production more efficient. Find out how HATAG AG worked with its Partner MTF Technik GmbH to develop a solution that met all customer requirements and increased the customer's productivity.

Tailor-made solution for a Swiss stamping company

A Swiss stamping company was looking for a tailor-made solution to make its production more efficient. He had the following requirements for the machine and turned to HATAG AG for implementation:

- His punched parts came from two different tool openings

- The pieces should be counted and then buffered in two separate containers.

- The punching machine could not be stopped when changing the container.

- The press had to be easily accessible for set-up purposes.

The result

In cooperation with its partner, MTF Technik Hardy Schürfeld GmbH in Germany, HATAG AG developed the individual solution for the customer. The result can be summarized as follows:

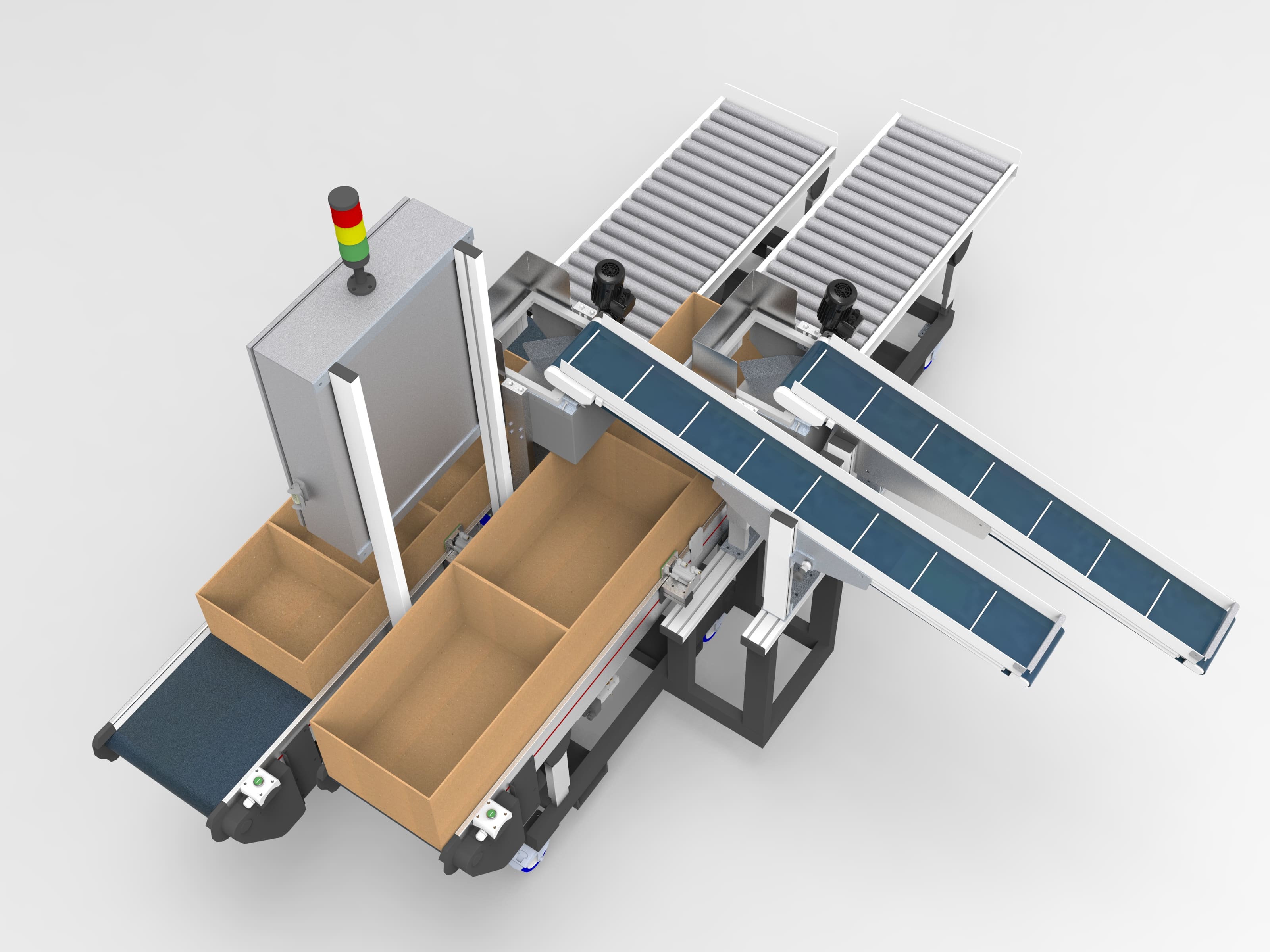

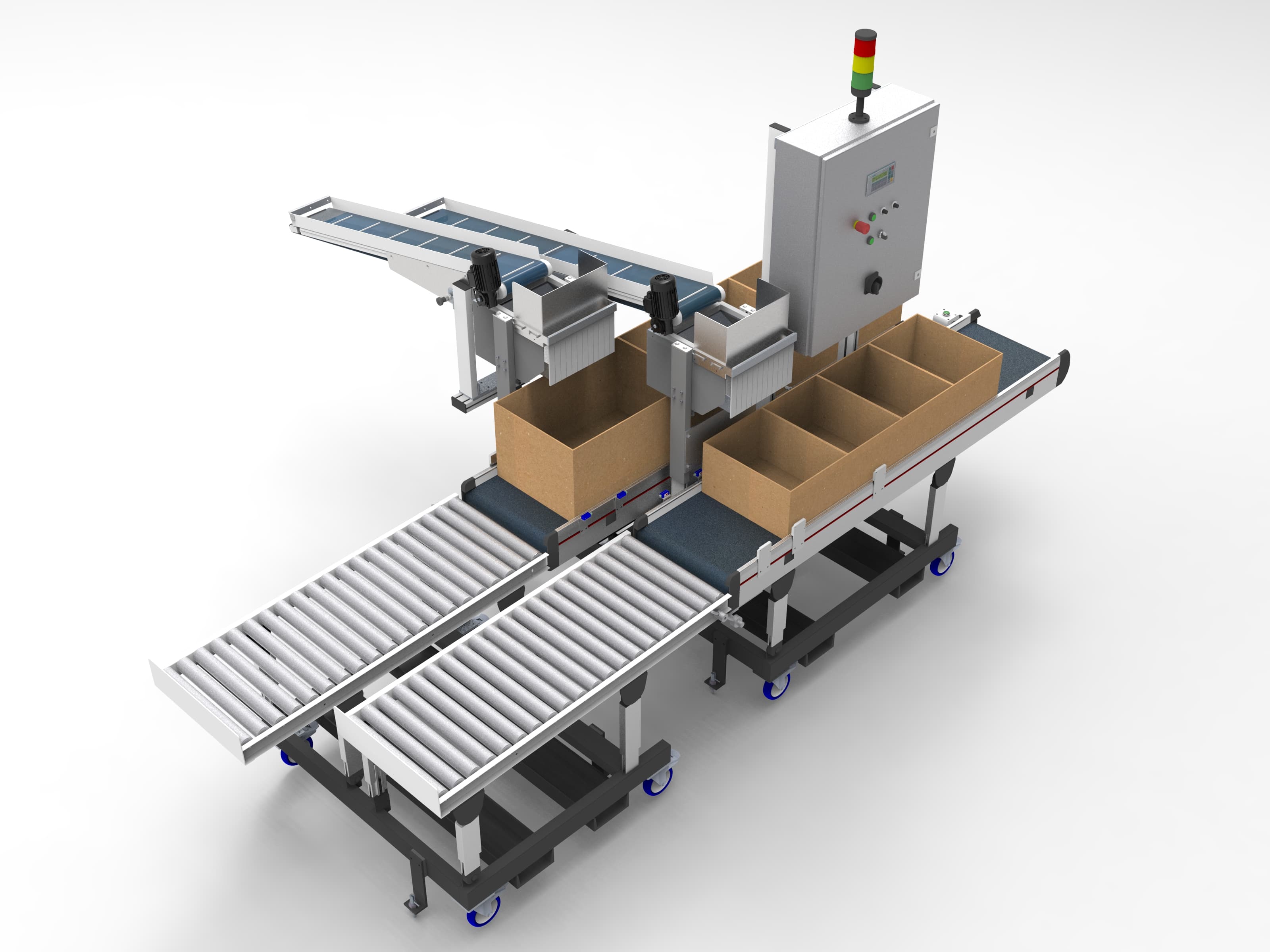

- Two I-Tech small conveyor belts transport the stamped parts out of the press area.

- Frame light barriers are mounted under the conveyor belt outlets, which detect and count the parts as they fall through.

- The components first fall onto a pneumatically swiveling chute and slide over it into the respective container.

- The containers are fed on two parallel Multi-Tech belt conveyors type GL and positioned via corresponding light barriers and pneumatic cylinders.

- After reaching the nominal number of pieces per container, the corresponding chute swivels into an intermediate position in which the components are caught during container changeover.

- When the next container is in position, the chute swivels back to the starting position, and the temporarily stored punched parts reach the new container.

- Filled containers runoff via a gravity roller conveyor and can be removed by the operator.

- The I-Tech conveyor belts can be swiveled into a vertical position when working on the punching tool and locked there. This means that the entire system can be moved away wholly to save space if it is not needed for a longer period.

Are you also looking for a tailor-made solution for your individual requirements? HATAG AG is your contact when it comes to supply for your production.