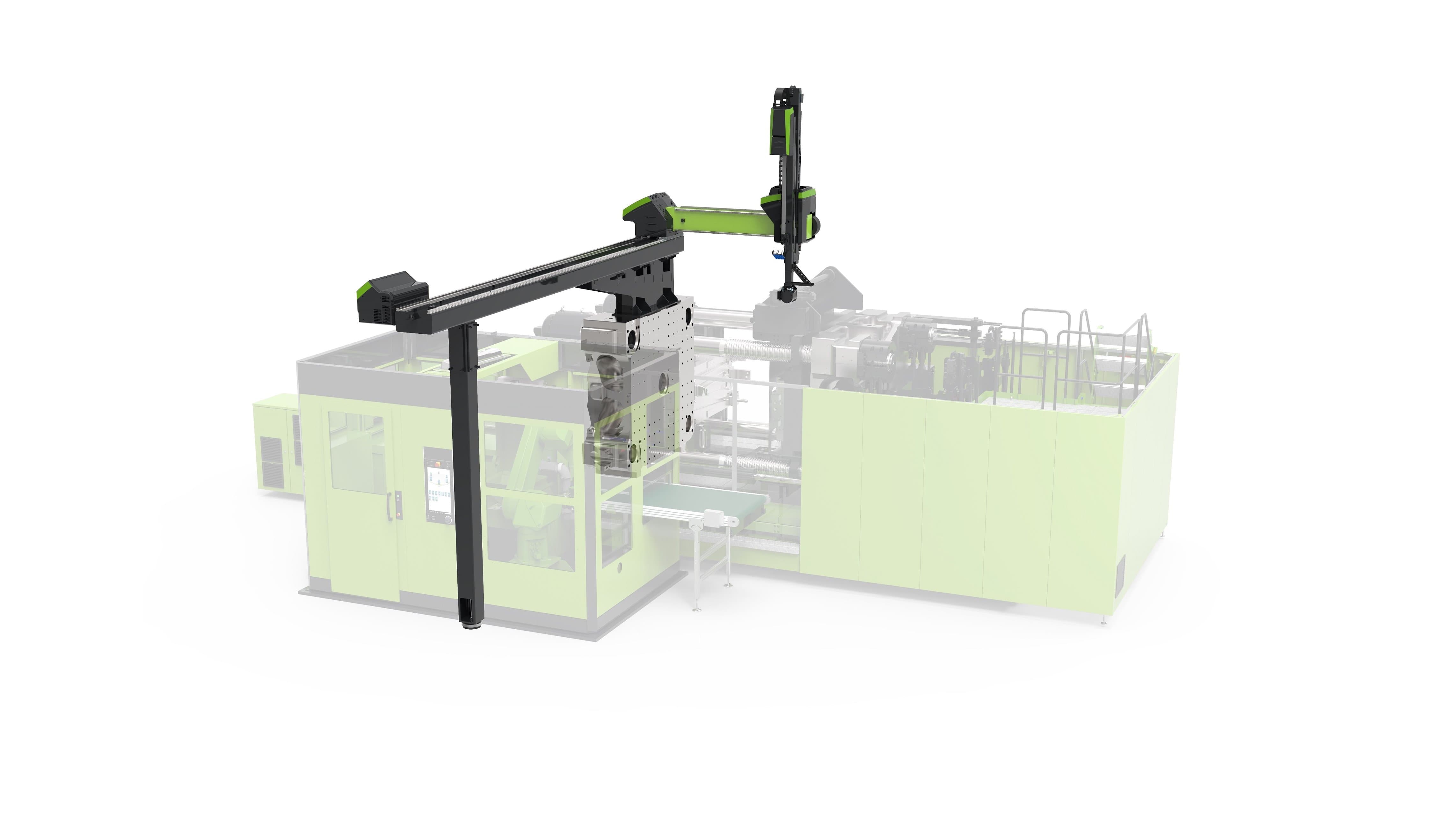

ENGEL viper: innovative technology meets flexibility

ENGEL robots guarantee the optimisation of all injection moulding applications with the aid of innovative technology: the ENGEL viper linear robot ideally complements an efficient and durable production cell.

Automation of production: everything from a single source

For 40 years, ENGEL has been developing and producing components for production automation that are perfectly matched to injection moulding solutions. Mechanical and control integration results in compact solutions that guarantee the highest part quality, stable processes and maximum productivity.

Flexible use and maximum output

The high-performance linear robot has the flexibility to be used on machines of any size and offers improved load-bearing capacity with a low deadweight thanks to its innovative design. Smart software packages ensure that all movements are perfectly harmonised.

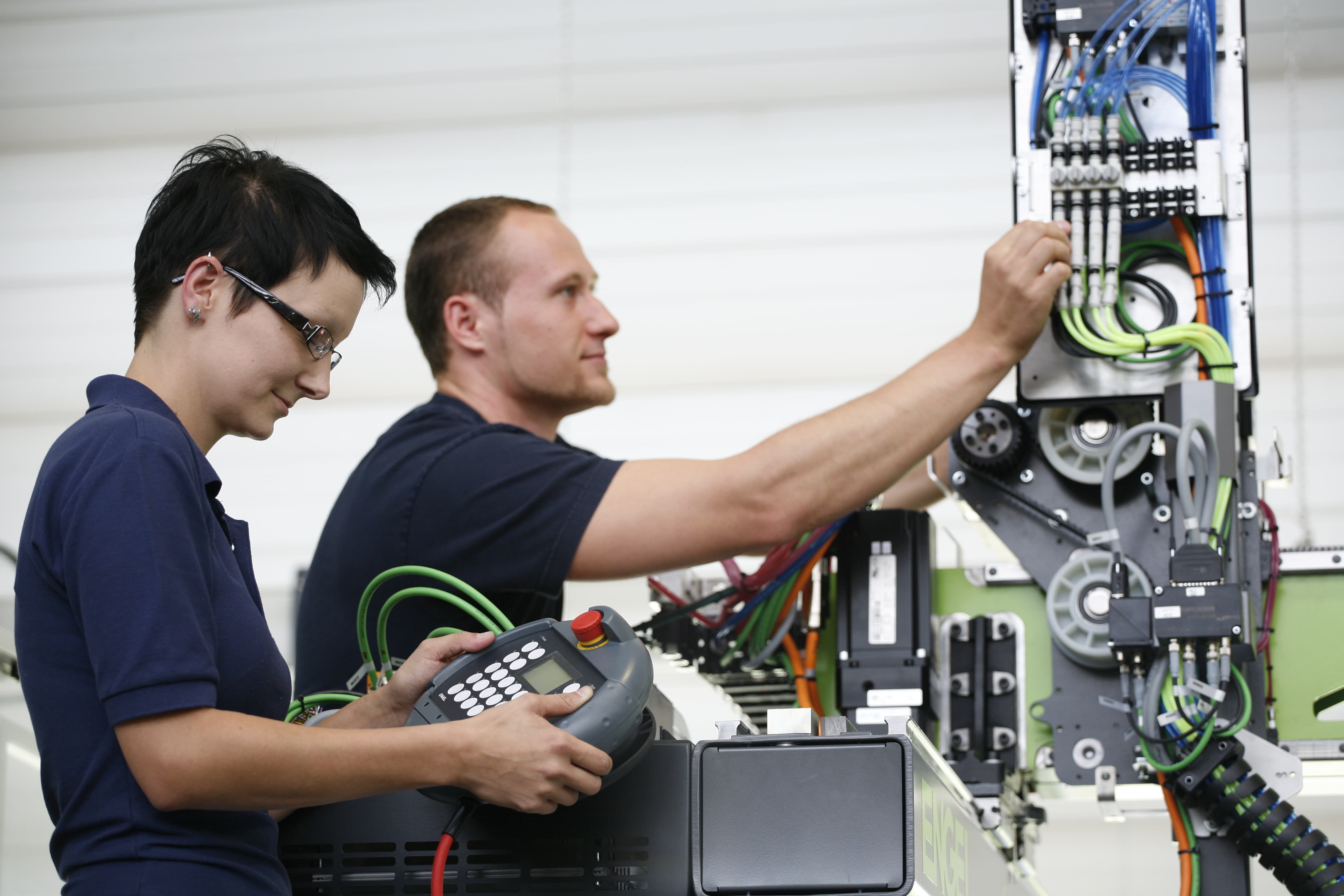

Integration of the robot and peripherals in the CC300 machine control unit

The central, uniform operating concept based on the CC300 machine control unit ensures simple and safe operation minimising the training time for operators and enabling faster commissioning. In addition, sharing part and data management between the machine and robot guarantees the best possible mould set-up and improved process quality. Real-time synchronisation of machine and robot movements is a further major advantage which promises shorter cycle times, collision avoidance and an arbitrary number of mould functions.

Multidynamic

Multidynamic sets new standards for performance and efficiency in the use of linear robots. The software automatically adapts the speed of the robot movements to the current load and thus shortens the cycle time in many applications. The plant operator does not need to manually optimise the robot speed, a fact which accelerates the production process start-up. Multidynamic delivers precision with the maximum service life and enhanced safety.

iQ vibration control

The dynamic ENGEL iQ vibration control uses 3-D motion sensors to detect the robot's vibration and actively compensates for vibration triggered by external influences. The optimised motion sequence ensures fast and precise positioning. This guarantees greater orbital and positioning accuracy for long axes and heavy grippers, faster part removal and pick times in the event of machine vibration or other influences, and a maximum service life.

Hard facts | viper

- optimised efficiency – maximum output and less energy consumption

- more convenience – particularly safe and easy to operate

- low life cycle costs – durable design and low maintenance costs

- variable use – stand-alone linear robots, integrated in ENGEL injection moulding machines, or as stand-alone solutions for other brands.