Frequently asked questions about computed tomography

Industrial computed tomography has become indispensable for non-destructive material testing. For your full view though, MessX AG clarifies the most important questions concerning the imaging process.

For your full view though

Non-destructive industrial computed tomography reveals quality and process deviations. MessX AG addresses the most important questions regarding performance and possible applications so that you can check whether the procedure can also solve your challenges.

Up to which maximum size can MessX scan components?

Components with a dimension of Ø 360mm and a length of 400mm can be scanned. Since the component is rotated 360° during the CT scan, the maximum dimension can be imagined in the form of a cylinder. Larger components can be scanned with a "Multiscan". Several CT scans are distributed over the component and then reassembled. The basic limit is that the component still fits into the cabin of the CT system and can ideally be rotated 360° for the scan.

Do the parts have to be pre-treated before a CT scan?

No, no pre-treatment of the parts is necessary and we do not pre-treat them in any way.

Can a CT scan be applied on all materials?

A lot of materials can be scanned, also parts e.g. made of steel. Since a CT scan is performed with X-rays, and the condition is that the X-rays can penetrate the sample to be examined entirely and in all directions, the maximum wall thickness is predominantly decisive for denser materials. With our CT systems, we can scan steel parts up to a wall thickness of approx. 20 mm. With plastic parts, this limit is many times higher, as they have a much lower density.

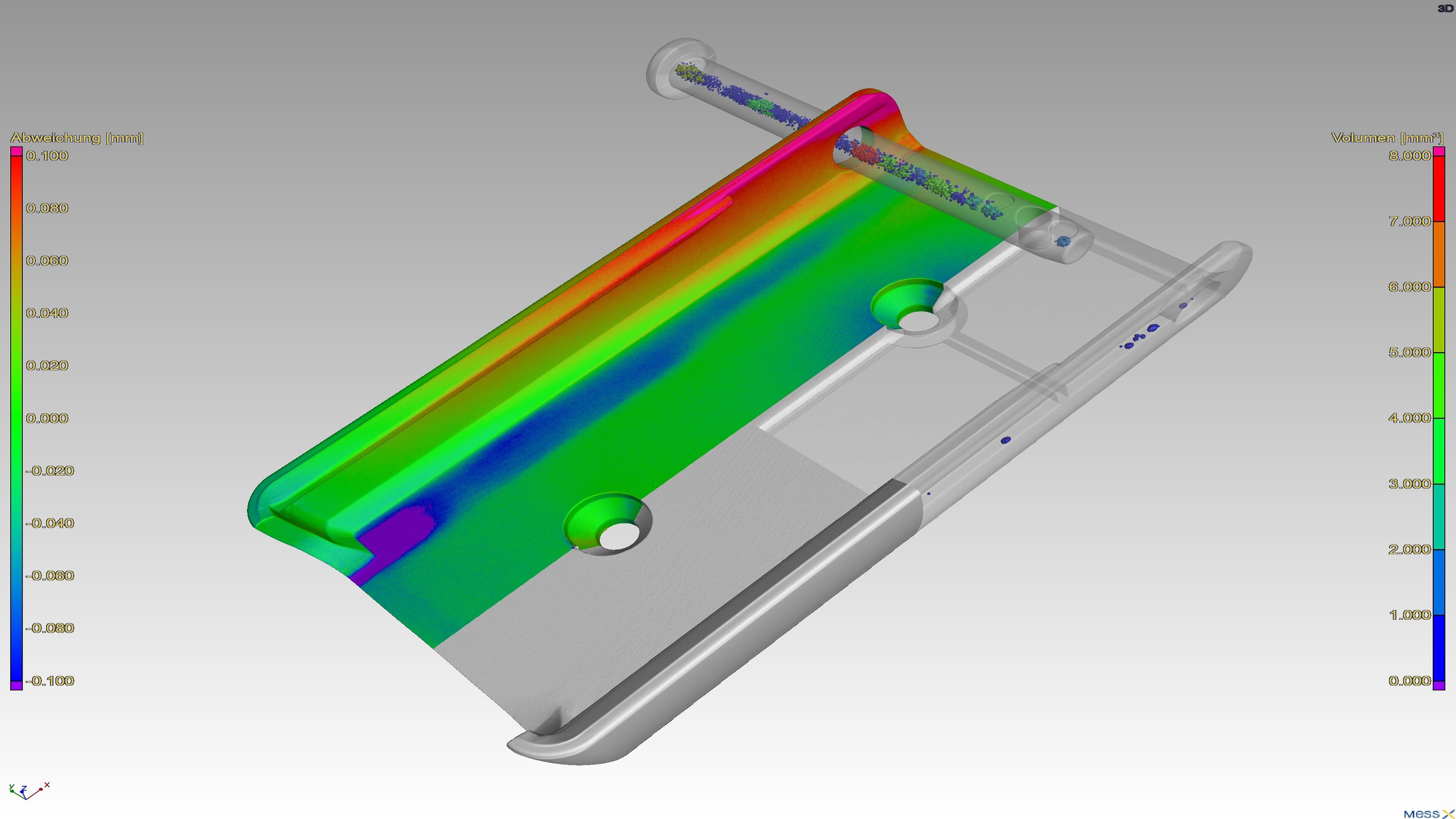

With what accuracy can the CT data be measured?

Our CT systems are validated according to VDI/VDE 2630, sheet 1.3, and have a system accuracy of SD (TS) ≤ 3.8µm + L/100. (SD: Ball center distance deviation | L: The length to be measured on the component)

Example: A diameter of 50mm is therefore subject to a maximum length measurement deviation of +/- 4.3µm.

What is the difference between resolution and accuracy?

The resolution primarily allows a conclusion to be drawn about the possible detail detectability. If, for example, pores with a diameter of 0.2mm are to be searched for in a material, a voxel size (resolution) of ≥ 0.2mm is not sufficient to reliably determine the dimensions of the pores found; the resolution of the CT data should be significantly higher in this case.

The accuracy indicates the maximum deviation of the measurement results (see the question "With what accuracy the CT data can be measured?").

What is the maximum resolution with which CT data can be generated?

With our CT systems, resolutions of < 1µm can be achieved. However, some conditions must be taken into account, such as component dimension and material.

How long does an examination via CT, including evaluation take?

We have a maximum lead time of 3 working days after receipt of the components. The lead time depends of course on the desired scope of evaluation or analysis.

Can several parts be scanned in one CT scan?

Yes, if the required resolution (detail recognition) of the CT data, as well as the component dimension and density of the material, allow it, several components can also be scanned simultaneously in one CT scan.

What does a CT scan cost?

In case of an inquiry, we check the feasibility on the one hand and on the other hand also which technical possibility will deliver the best results and this, of course, taking into account the economic efficiency. As every inquiry is thoroughly checked and the requirements are very different, the expenses are also very different. Therefore, this question cannot be answered conclusively. Of course, we would be pleased to prepare a non-binding offer, tailored to your needs.