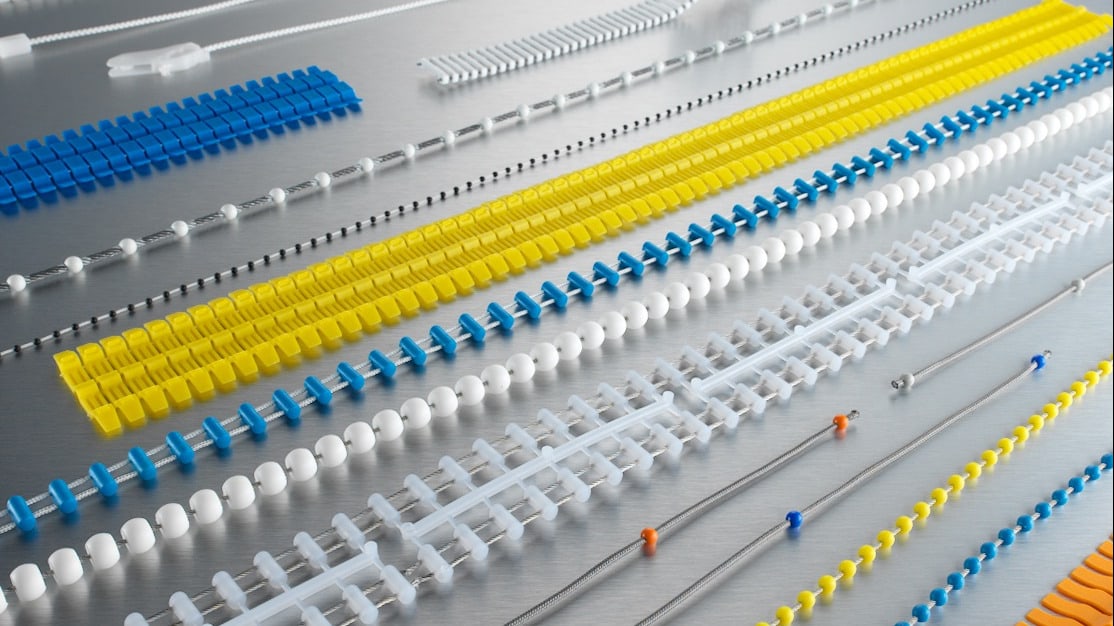

Over-moulding of functional geometries onto carrier bands

The CardaFlex®-technology enables precise and continuous over-moulding of diverse functional geometries onto different carrier bands to produce force transmitting parts.

Individually parts designed for specific applications play an important role in the equipment industry, especially when manufacturing household appliances. Force transmitting functional parts, drive and gear elements require in particular to be over-moulded according to the specific application.

These specific requirements are met with the CardaFlex®-technology: functional geometries are moulded onto different carrier bands. In general, all thermplastic elastomers can be used to over-mould. The material of the carriers can either be chemical or textile strings, or even steel strips and cables.

As a competent partner in the development and production of plastic assemblies and parts, SFS intec applies modern and automated lines to create optimal manufacturing conditions. At its core focus is the mastery of all processes. For example, the concept of process-integrated automation ensures here a high economic efficiency with respect to manufacturing and assembly of CardaFlex® solutions.