Research and development Connection technology

Are you looking for the right joining technology for a specific challenge? Our institute is your partner for research and development in the field of connection technology. We will find the right solution for you in applied research through the use of new joining processes and new materials.

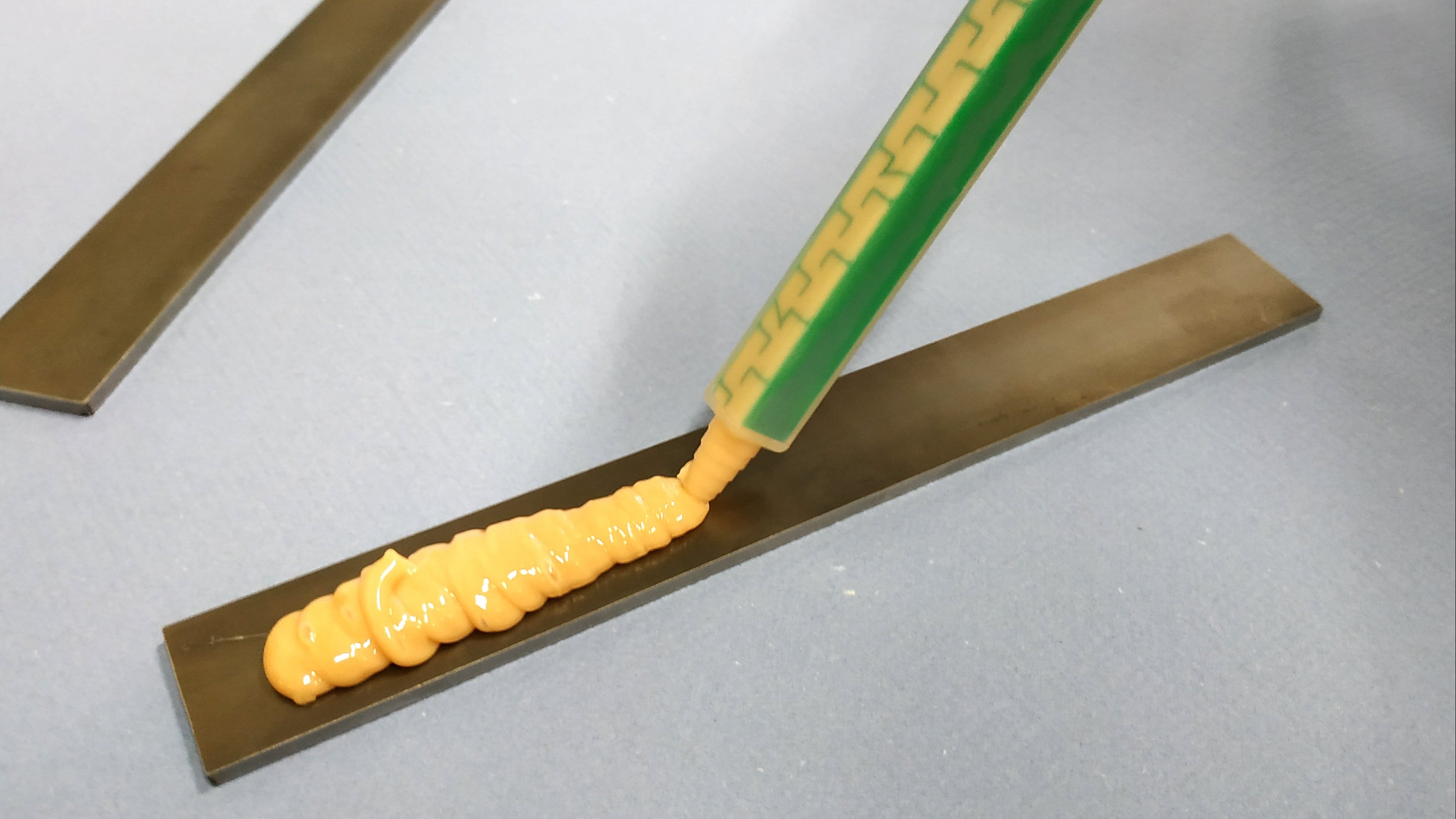

Complex and innovative lightweight products in multi-material construction are only made possible by the right joining technology. In addition to traditional joining techniques such as screwing, riveting or welding, processes such as bonding or ultrasonic welding allow the design of innovative material combinations with optimized material properties and are therefore key technologies for lightweight construction. The IWK Institute is researching new methods and developing new solutions for industry.

Use of new joining processes with new materials

The Joining Technology Group deals with the dimensioning, optimization and production of material combinations and their joining processes in research and development. The modern laboratory infrastructure and calculation capacity of the IWK are available for these activities.

Core competencies of the department

- Laboratory testing of joined specimens and components

- Identification of material parameters

- Analytical calculations and finite element simulations

- Preparation of compounds

Many years of experience in connection technology

In particular, the IWK has extensive experience in the design and dimensioning of bonded structures and in the testing and FE simulation of adhesive joints, from the area of small deformations to complete failure in the non-linear plastic or hyperelastic area. The focus here is on the use of new joining processes with innovative materials.

Our interdisciplinary approach enables synergies and knowledge transfer across all IWK departments and in intensive customer contact with industry.

Department of Joining Technology

- Selection of joining processes

- Material selection and design of joints

- Dimensioning with analytical and numerical methods (FEM)

- Substance data determination: Direct and inverse identification of material parameters for analytical calculations and FEM

- Microstructure and damage analysis

Fields of application

Joining processes are nowadays important for all areas of industry: from tiny microstructures in electrical engineering areas to huge structures in aviation or wind energy. Questions concerning the joining technology of material combinations are also topical in the construction and transport industry.

Our modern equipped machinery

process technology

- Rinco ultrasonic welding unit

- SpeedMixer

- Adhesive devices for tensile, tensile shear, TAST, SZ, DCB

- ENF and MMB samples

- Plasma device Piezobrush® PZ2-i

- Manual Flame Arrester SurA FB 07 Pyrosil

- Test and measurement technology

Fatigue testing machine Dynamess

- Fatigue testing machine Sincotec

- Digital Image Correlation System (DIC) Aramis GOM

- MSA (Mobile Surface Analyser)

- IPT, creep test machine

Special testing devices

- DCB (Double Cantilever Beam), ENF (End Notched Flexure specimen) and MMB (Mixed-Mode Bending specimen)

- Wedge impact for wedge impact method according to ISO 11343

- Planar, biaxial and volumetric pressure testing for elastic adhesives

Software

- Computer Aided Engineering in connection technology

Contact us with your challenge in the field of fastening technology for an initial, non-binding discussion.