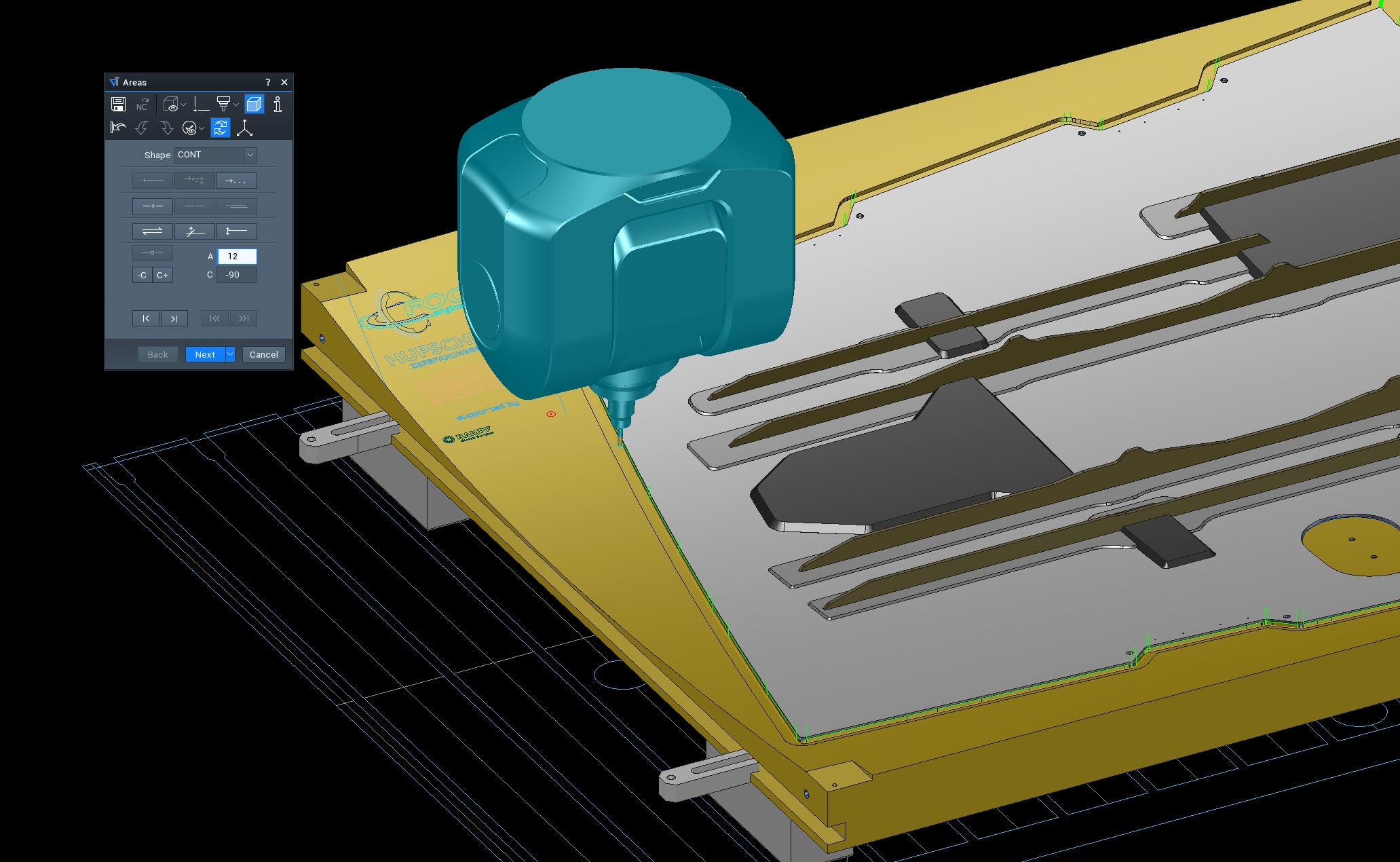

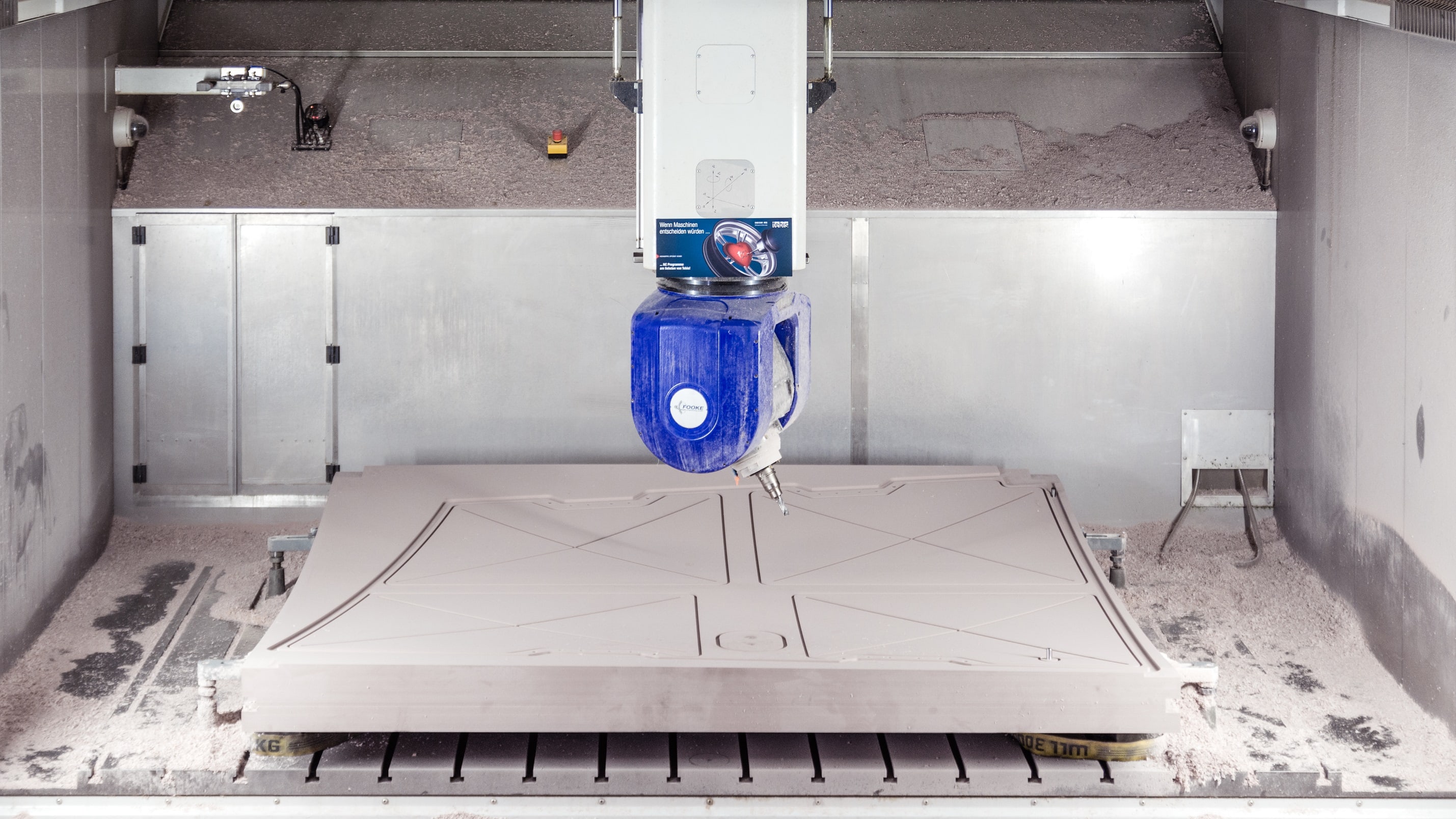

2 successful online events are behind us, which we were able to hold together with our partners Tebis AG and FOOKE GmbH. The topics ranged from digital twins to the production of a vacuum clamping device made of polyurethane block material. Learn more about the highlights here.

Using the example of a CFRP wingshell, the production of a vacuum clamping

device from polyurethane block material and delamination-free cutting and

drilling of carbon fiber composite with special tools were demonstrated. Tebis

explained how to create a digital twin despite the lack of CAD data. The 45-

minute seminar sections, each separated by a half-hour break, were followed by

a lively round of questions and discussion.

"Our online events with partners have become an attractive way to bring

together more machining professionals on a topic than might be expected at an

in-house event. The participation right to the end and the queries showed how

interested the participants were in listening," says Heiko Simonis, Business

Development at Hufschmied Zerspanungssysteme GmbH and one of the

speakers. For example, people asked about experiences with other composite

materials, about the linear drives of the FOOKE Endura 715 and about reverse

engineering in Tebis. There were also very specific inquiries about cutting data

and ordering BlockBuster tools.

Holistic machining concept convinces

In their feedback, participants praised the compact form of the event, the

technical depth of the presentation and the competence of the speakers.

Andreas Rist from Huber Kunststoff & Technik GmbH, a mold and model maker

from Wiedergeltingen, said: "Since fiber composite technology is an important

part of our range of services, both parts of the Masterclass "Vacuum clamping

fixtures and CFRP component trimming, trim milling & drilling" were very

interesting for me. Hufschmied, Tebis and FOOKE did a good job of presenting

a practical example. Once again, it became clear to me that with Hufschmied,

we have an ideal partner for material- and process-optimized machining

solutions at our side. We have been allowed to benefit from the innovative and

promising solutions of the Hufschmied company for many years."

International version will follow

Following requests from abroad and the many positive responses, Hufschmied,

Tebis and Fooke plan to repeat the event in English. The presentations and

video summaries are now available to the public:

Videos:

Designing and Manufacturing Vacuum Clamping Fixtures

Trimming CFRP components: trim milling & drilling

Abbreviated presentations:

Design and manufacture vacuum clamping fixtures

Trimming CFRP components: trim milling & drilling

Available images

Images can be downloaded from the Internet in printable quality.