We provide manufacturing companies with high-speed, high-performance machines that are extremely efficient and deliver absolute precision with exceptional reliability.

We provide manufacturing companies with high-speed, high-performance machines that are extremely efficient and deliver absolute precision with exceptional reliability. Our products undergo continuous development to meet your needs, with the purposeful incorporation of innovative technologies to ensure your production is constantly efficient and sustainable. Applying our specialist know-how and experience, we actively advance the development of digitization and a sustainable circular economy.

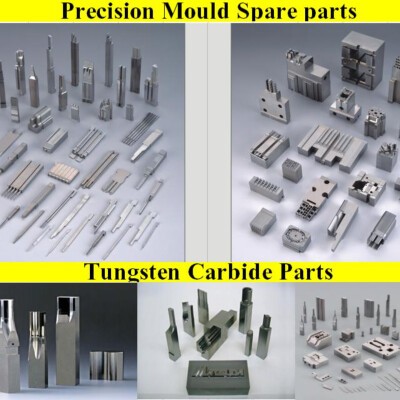

We develop our machine portfolio to provide performance, precision and quality. Our range consequently features all-electric and hybrid injection molding machines of the Elios and Elion series with clamping forces spanning 800 to 10,000 kN and the state-of-the-art PET-Line preform system for up to 144 cavities. To provide turnkey system solutions from a single source, we maintain a network of leading and highly specialized industry partners for molds, handling systems and peripherals.