Coloured injection moulded parts thanks to direct colouring

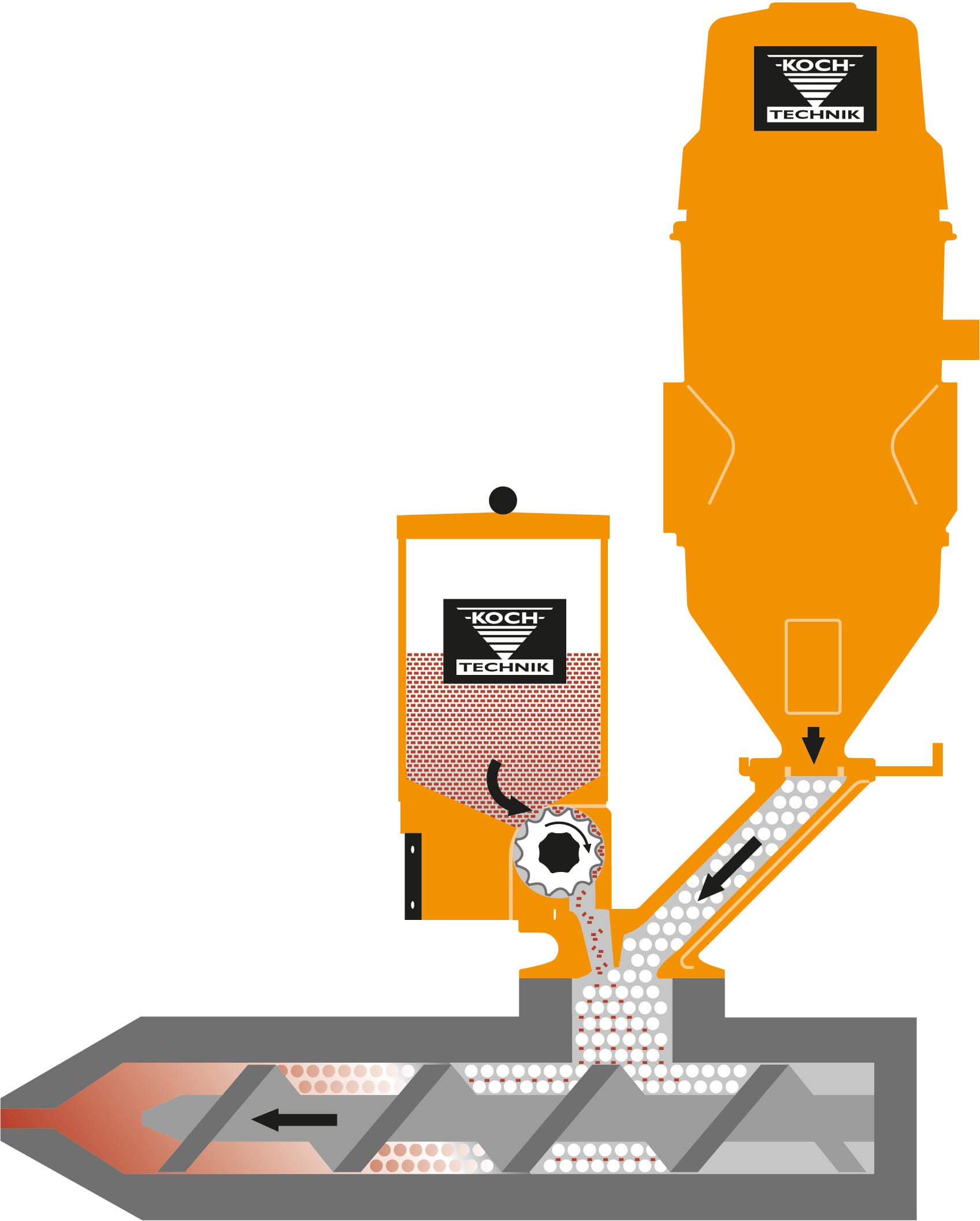

KOCH-TECHNIK offers a solution for exact dosing when colouring plastic parts. With KEM Direct Coloring, master batches can be used and the result is highly accurate.

When colouring plastic parts, the challenge lies in precise dosing and the simple use of masterbatches.

Hatag offers volumetric and gravimetric dosing solutions from Koch. These can be used to meter additives into a plastic material which is then processed in the injection moulding machine or extruder.

Exact dosages

KEM Direct Colouring achieves the highest accuracy when adding a masterbatch or additives to a main material. The desired dosing quantity can be infinitely adjusted and added to the main component. A start impulse either comes from the processing machine or is time-controlled. All necessary control components are integrated in the housing body, you only need a 230 V connection. This ensures that exactly the same colour tones are achieved during colouring.

Control of the KEM

The control of the KEM has:

- two programs for injection moulding machines

- two programs for extruders

After entering the ink percentage and the shot weight, the dosage is calculated. Up to 100 recipes can be stored in the memory. For use in extrusion, the controller can be reprogrammed to switch in cycles either as a function of speed or independently.

New motor for volumetric dosing:

On the KEM-TOUCH with control in the housing body, a stepper motor* ensures constant chamber volume dosing via dosing roller.

The advantages of this stepper motor with planetary gear are:

A high torque and holding torque for exact repeat accuracy and uniform dosing cycle a precise start/stop behaviour 60% less energy consumption.

We at Hatag would be pleased to advise you on the possibilities and solutions for your challenge in the colouring of plastics.