ENGEL e-motion: all-electric and high-precision

The ENGEL e-motion is an all-electric injection moulding machine for high-end applications. The right choice when both precision and speed are essential.

The right machine for high-end applications

Always faster. Always more precise. Always cleaner. These are the qualities of the ENGEL e-motion. Its strengths really come to the forefront when it is tasked with challenging applications, for example, in medical technology, fast-running packaging applications or electrical multi-component solutions. The carefully designed, flexible and all-electric machine solution delivers constant, clean quality.

Excellent cleanliness and durability

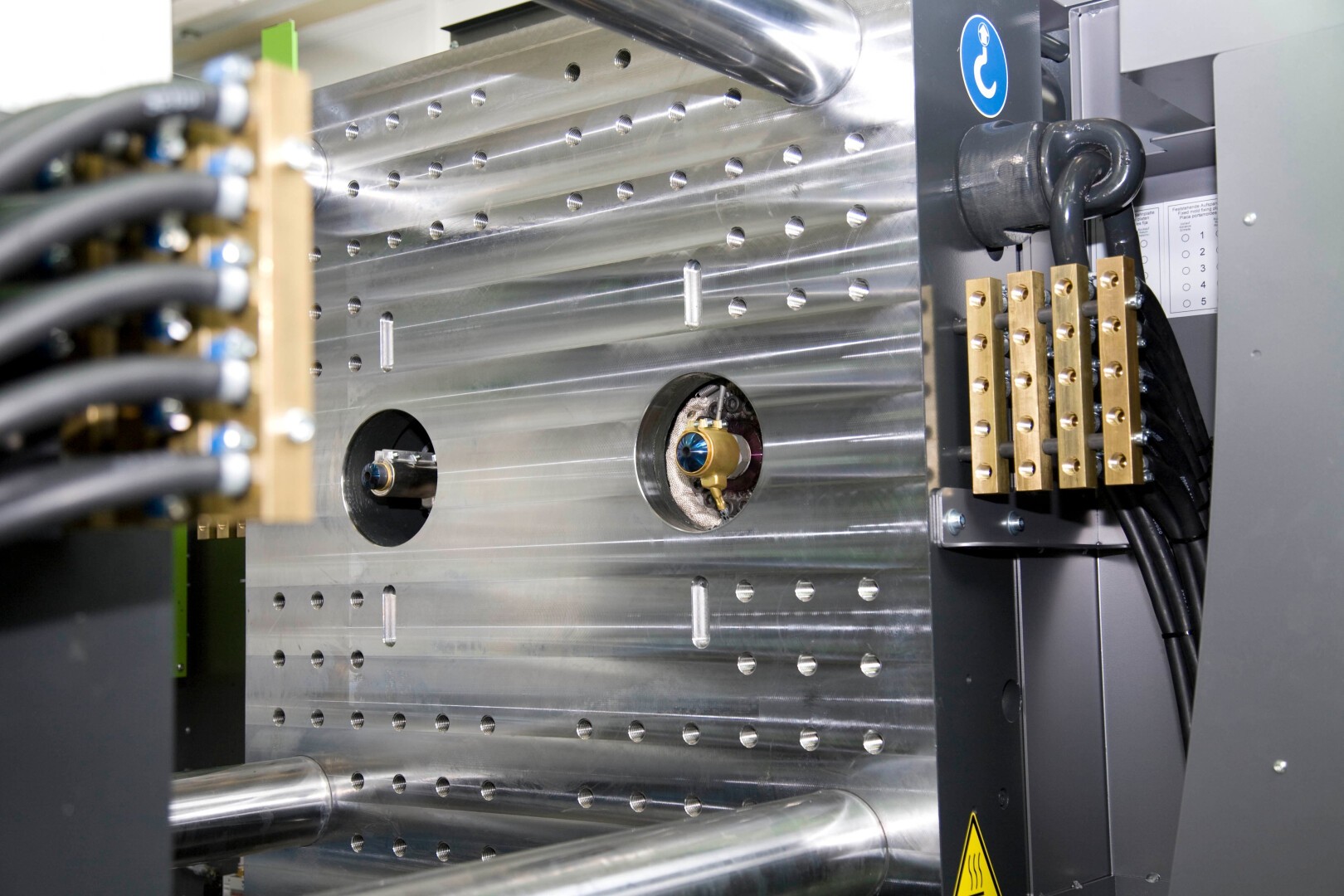

The ENGEL e-motion not only impresses with its sealed toggle lever and closed systems, which ensure a cleanroom-capable working environment, but it also produces in a particularly cost and energy efficient way. The enclosed system ensures the bolt is permanently covered in a film of oil which substantially improves the service life of all parts in question, while at the same time keeping maintenance costs low.

Energy efficient production

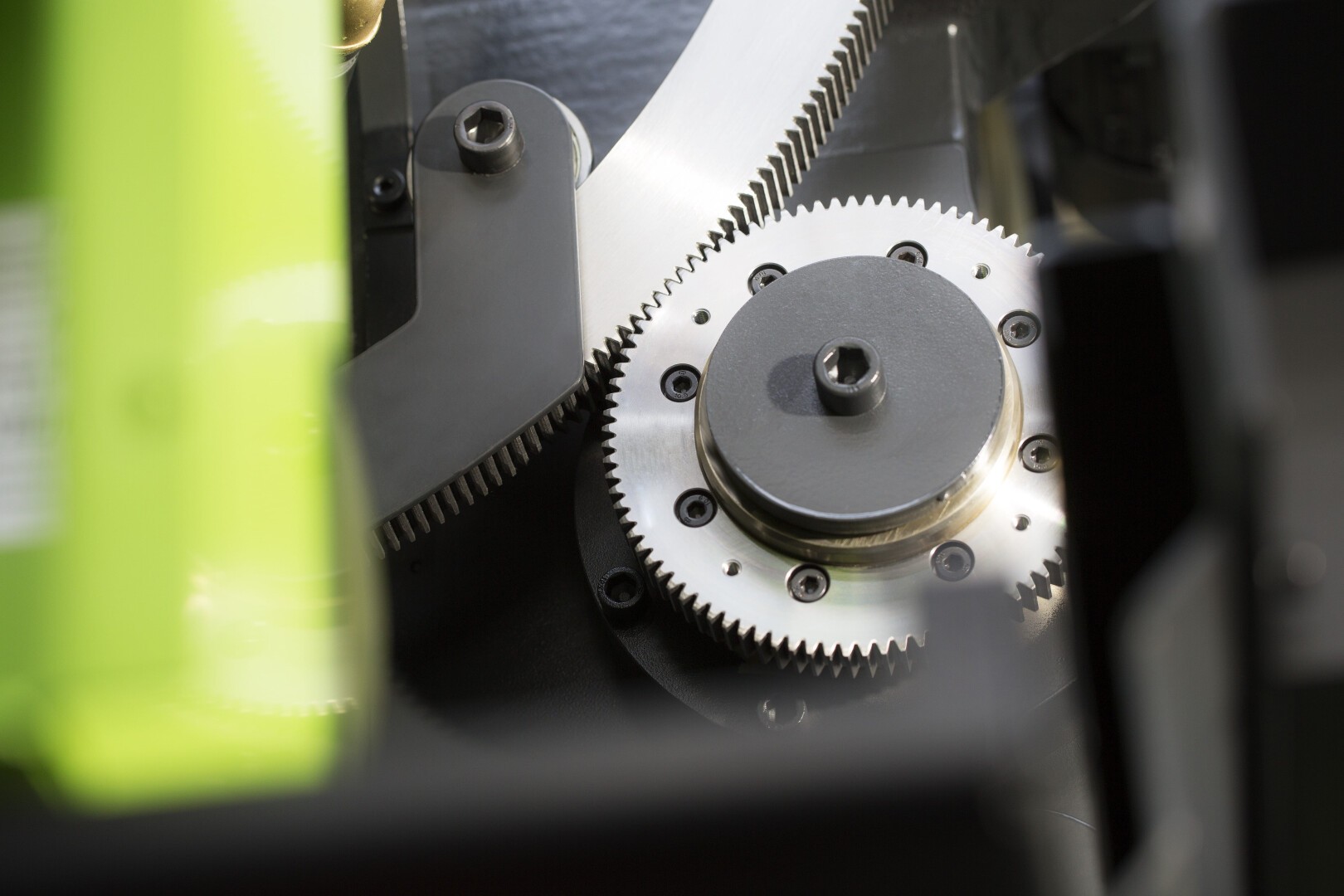

Dynamic servo motors with excellent acceleration ensure short injection times and particularly high performance. Highly efficient components in the all-electric injection unit ensure a perfect energy balance: greater output while cutting energy costs by up to 70%.

Hard facts | e-motion

- Low maintenance costs – durable injection moulding machines with a carefully considered, closed lubrication system

- Dynamics to the max – short injection times thanks to dynamic servomotors with breathtaking acceleration

- Efficient production – energy efficient drive design and great performance thanks to fast dry cycle times

- Precise & clean – cleanroom capability thanks to encapsulated toggle levers and precise linear guidance of the moving platen

- e-motion TL – all-electric machine solution with the proven tie-bar-less technology design

- Clamping force – of 300 kN to 6,500 kN