Our Polymer Solutions – Your customized compound

In order that your products to stay one step ahead of the competition, we develop your tailor-made polymers– known as compounds. With our experience, our know-how and our equipment, we develop your customized compounds.

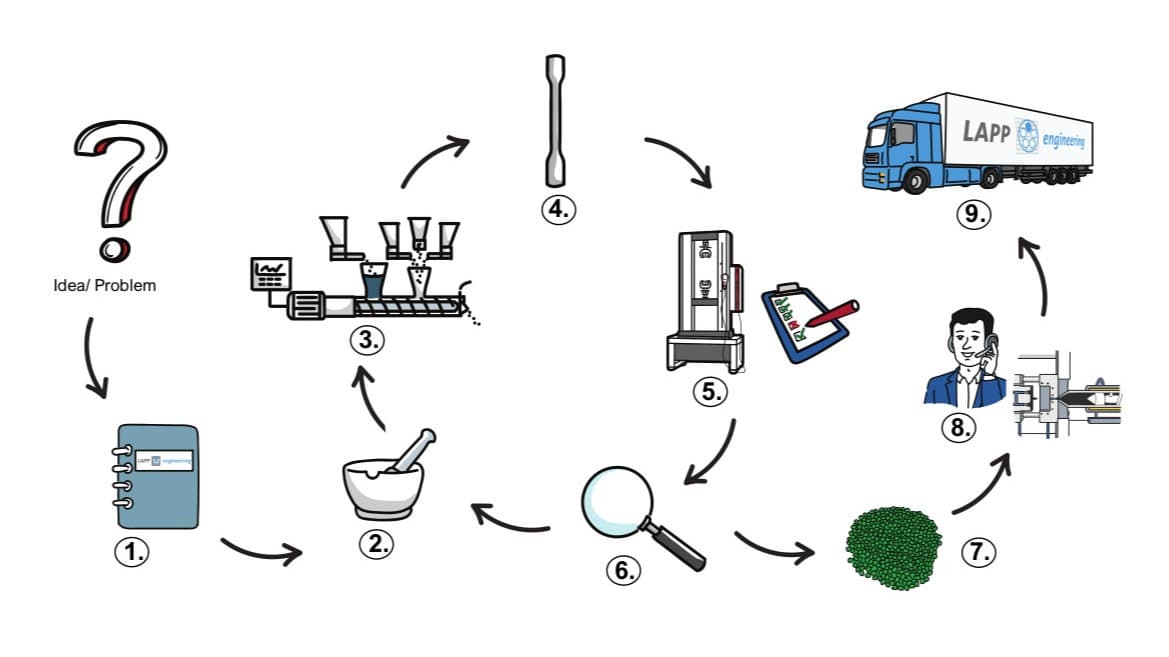

Our polymer solutions include three main steps:

| I. | Material development (step 1 – 6) |

| II. | Prototyping and pre-production (step 7 – 8) |

| III. | Material supply for series production (step 9) |

I. Material Development

The objective of the material development is the composition of a recipe for a compound that meets your requirements. To develop a compound successfully, several iterations are required, so-called development-loops. One iteration includes:

| Nr. | Step | Description |

| 1. | Specification | Together with you the requirements are defined. This provides the basis for the specification of material development. |

| 2. | Compound Recipe | Based on the specification, several recipes are formulated, usually 5 to 10. In addition, suitable raw materials for the recipes are procured. |

| 3. | Fabrication of Granulated Material | For each recipe, a test compound (granulated material) is prepared on the laboratory compounding equipment. |

| 4. | Preparation of Specimens | In our technical center between 10 and 100 specimens are prepared per test compound by means of injection molding, extrusion or compression molding. |

| 5. | Specimen Testing | In our laboratory the specimens run through mechanical as well as further project-specific trials. |

| 6. | Analysis | The test results are analyzed and compared with the specification. |

After completing the first development loop, a development agreement will be finalized. The development loop is performed several times until all requirements of the specification are met.

In the entire «material development» stage, the services of Lapp Engineering & Co. are generally free of charge for you.

II. Prototyping and Pre-Production

The objective is to produce prototypes from the tailor-made compound on your production lines. To this end, we will provide you with sample material and advise you on the process implementation.

| Nr. | Step | Description |

| 7. | Fabrication of Sample Material | Based on the final recipe, we produce sample quantities up to approx. 25 kg on our own compounding equipment. For amounts larger than 25 kg, we have the sample material produced by a qualified and experienced contract compounder on an industrial scale. |

| 8. | Service |

Our process engineering experts support and advise you in the production of prototypes on your equipment. |

At the end of this stage, your components fabricated with the tailor-made compound will fulfill your requirements. You are now able to produce large component quantities on your equipment.

III. Material Supply for Series Production

We are your material supplier and provide you with the required quantities and quality. Unlike a conventional material supplier, we can influence the recipe at any time. Together we are in a position to continuously adapt your products to market developments. This will strengthen your technology leadership.