Ultrasonic welding and ultrasonic cutting

From the standard machine to the customer-specific solution for OEMs, from the smallest component to the largest complete system: Each of our products contains unique technological expertise, embodies decades of experience and delivers enormous flexibility.

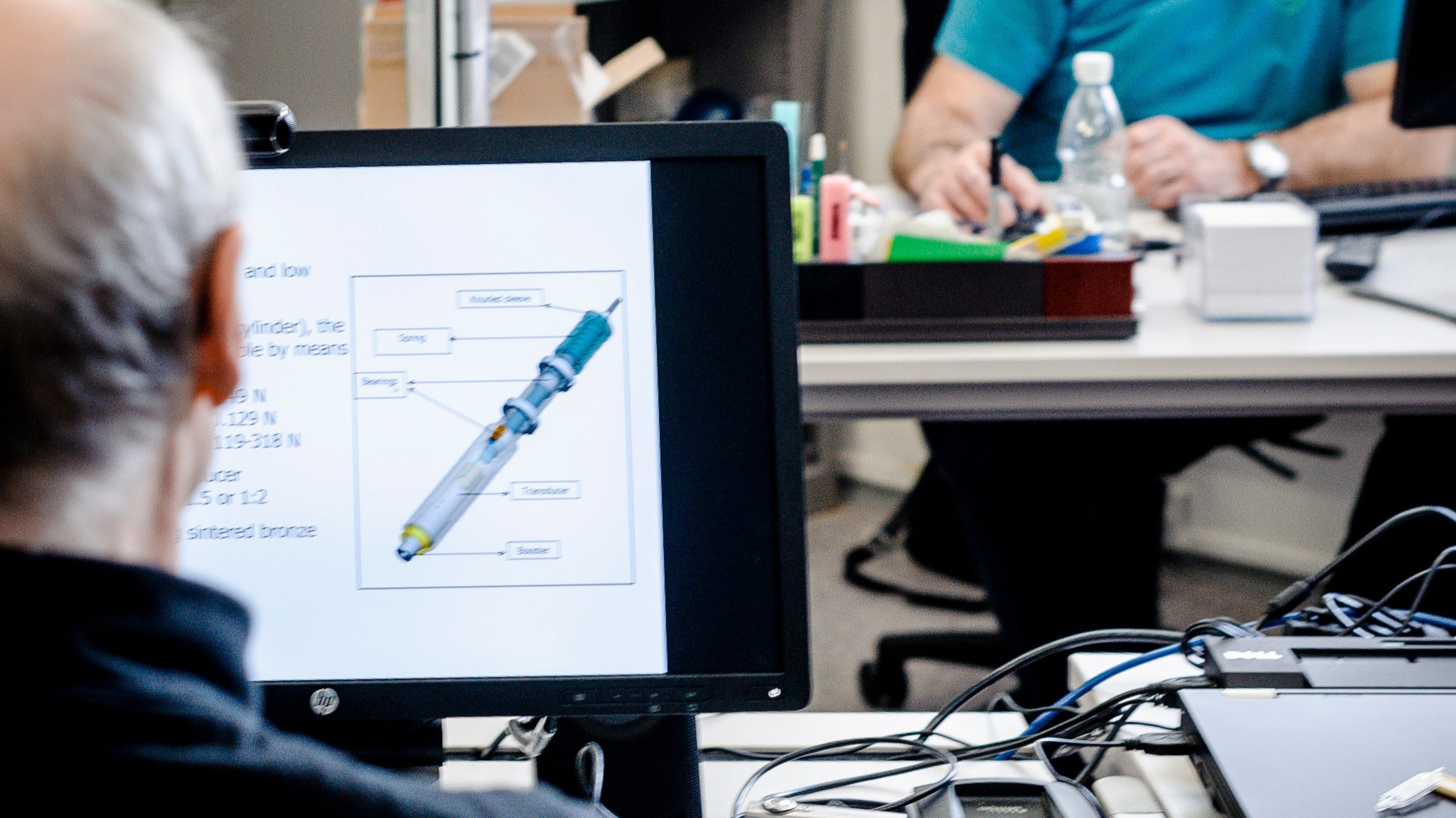

Ultrasonic technology

Welding, riveting, punching, diesinking, bending and sealing can all be carried out on thermoplastics and copolymers in the form of moulds or flexible shapes. A particularly suitable operation here is inserting, which allows metals and plastic components to be joined without pre-heating the metal components or damaging the application.

Ultrasonic-operations:

Welding

Ultrasonic welding is the most efficient way to join two thermoplastic materials. Without high energy consumption, films, injection moulded parts or synthetic textiles can be welded in milliseconds without leaving marks.

Sealing

The lightning fast sealing of packaging as it is carried out on modern production lines would hardly be imaginable without ultrasonic systems. They allow for much faster welding cycles than heat processes and guarantee an aesthetically impeccable result.

Cutting

Ultrasound allows materials to be cut without residues on the tool. Therefore, the process is just as popular in the food industry as it is in textile processing, where, among other things, it guarantees cleanly cut edges without fringes.

Inserting

During inserting, metal parts are pressed into moulded parts using ultrasound. The advantages are high speed, low energy consumption and accuracy. What is more, the metal does not have to be preheated.

Punching

Ultrasound is one of the cleanest and quickest punching methods: With thermoplastic materials, beautiful, rounded edges are created automatically without any white breaks. With synthetic textiles, cut edges are cleanly sealed during the punching process.

Fusion forming

In fusion forming, thermoplastic materials are riveted or flanged with other materials. This results in rigid connections without any play, which are characterized by a very long durability.

The highest levels of quality for welding results, wellchosen materials for tools and absolute process control thanks to recording software for validation purposes and quality assurance. RINCO offers you everything you need for a production process at the highest level.