From discussion at a trade fair to company merger

As the crow flies, the distance between the two companies Torson Kunststofftechnik AG and Injex AG in Zurich was barely 350 m. But they only became acquainted at the 2020 Swiss Plastics Expo in Lucerne. Today, these two companies are working towards a common cause – as Torson Injex AG.

Text: Roger Amberg / Photos: Torson Injex AG

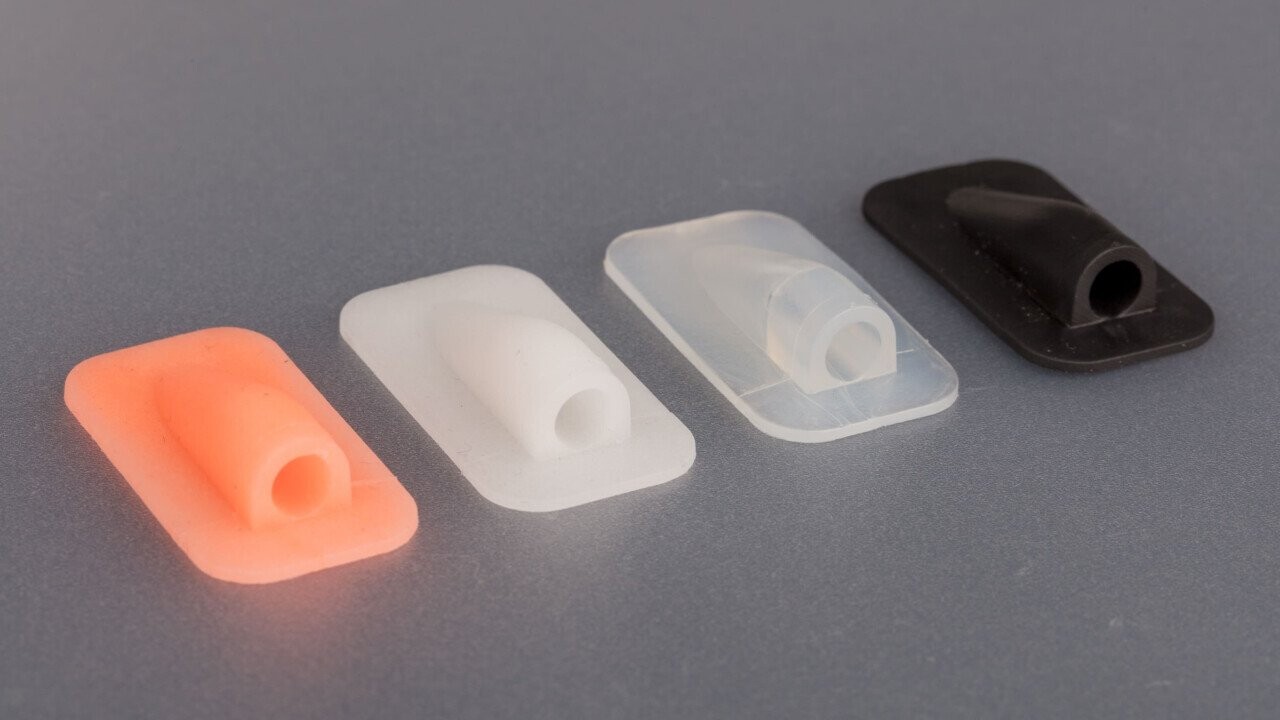

Swiss Plastics Expo in Lucerne, at the beginning of January 2020: The fairly recent start-up Injex presented its additive tooling concept for the first time at the plastics trade fair. Under this concept, 3D printers are used to fabricate injection molding tools with the aim of manufacturing near-production quality prototypes in a short time. While looking for new customers and partners, the co-founders Oliver Schlatter and Tobias Ammann engaged in a conversation with two visitors to their stand – who turned out to be Lorenz Camenzind and Peter Joder, the owners of the company Torson. In contrast to the Injex start-up founded in 2017, at that time Torson was already an established and renowned company with more than 60 years' experience in the production of plastic parts. The company has specialized in using an injection molding process to manufacture customer-specific connector solutions.

The twin that is 60 years older

It soon became clear that the two companies had much in common. Oliver Schlatter, now the CEO of Torson Injex, still remembers this meeting very well: "It was totally surreal. When they introduced their company and their concept, I thought they were kidding me. They were basically doing the same as us, and their head office was located just 350 meters from ours." The two companies were on the same wavelength, not only in terms of location, but also when it comes to ideas. "We both had an unconventional approach and mostly worked with machines we designed ourselves rather than with commercial injection molding machines," explains Oliver Schlatter.

Meeting at trade fair leads to merger

The discussion at Swiss Plastics Expo went so well that the parties met up several times throughout the year. It turned out that the Torson owners were looking for a succession plan for their company. "They were enthusiastic about the way we had built up our company, and they saw themselves in us as young tinkerers and inventors," says Oliver Schlatter. The discussions ended with the start-up Injex taking over the traditional company Torson in the same year, less than a year after they met at Swiss Plastics Expo.

«As a start-up, you have to think long and hard before you take such a step and go in a different direction than originally planned»

Oliver Schlatter, CEO Torson-Injex AG

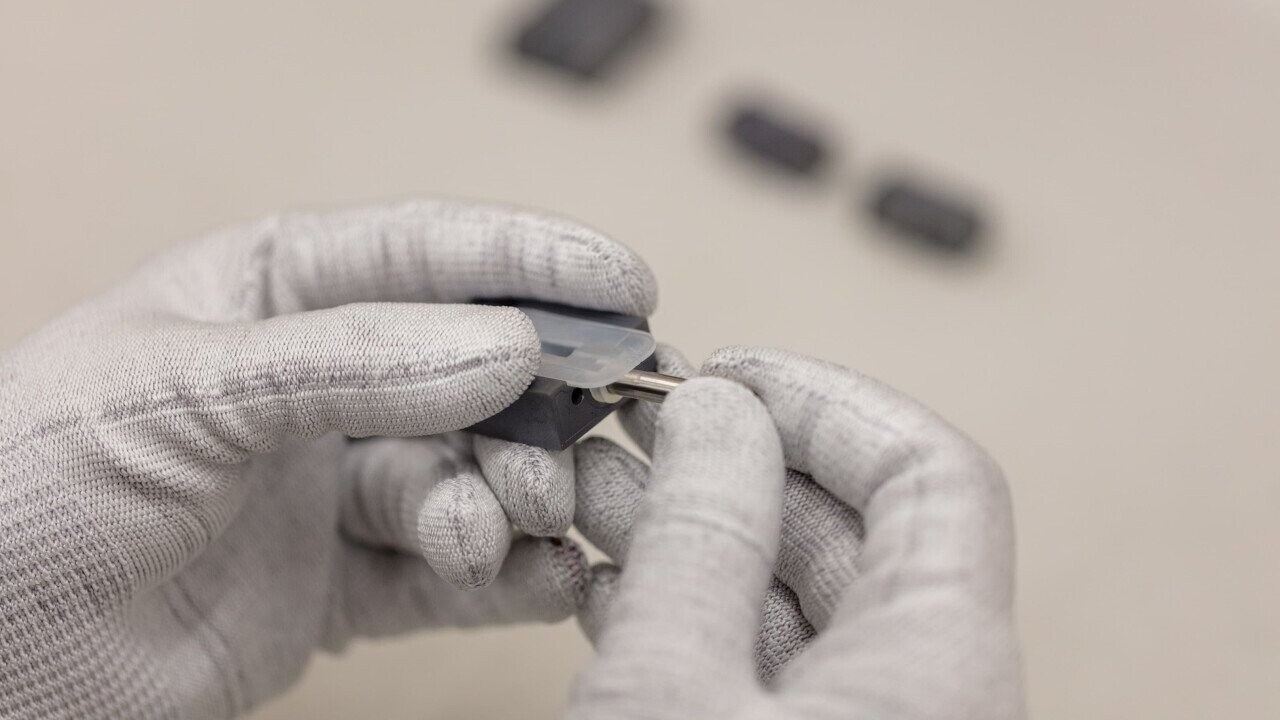

Both companies saw a merger as the ideal opportunity to combine their two specialist areas. The additive tooling process of Injex and the agile injection molding system using the small-format Torson injection molds enable the manufacture of both near-production quality prototypes and large-scale complex plastic parts in a short time. This makes it possible for a single provider to develop prototypes as well as handle series production.

A bold decision in a difficult time

For the small start-up Injex, the merger which expanded the company from 6 employees to 30 was a big step, confirms Oliver Schlatter: "As a start-up, you have to think long and hard before you take such a step and go in a different direction than originally planned. But it was a great opportunity for us to grow quickly." Conditions were not ideal, however, as the takeover took place in the midst of the difficult corona pandemic. "We needed more than just a healthy dose of courage to take such a step in this situation," explains Oliver Schlatter. But thanks to the broad-based support of their customers, both companies weathered the crisis well. During the takeover, the support and acceptance of the Torson employees were particularly helpful in ensuring a smooth transition, and all of them were incorporated into the new company structure.

Into the future with optimism

By now, the new company Torson Injex has proven itself, and wants to grow even further going forward, says Oliver Schlatter: "The combination of supplier and producer of serial products on the one hand and developer of customer-specific solutions and prototypes on the other offers a great deal of potential. We want to continue charting this course and develop further." Torson Injex will have its next opportunity for growth and connecting with potential customers in September this year. Oliver Schlatter and his company will again be guests at Messe Luzern, this time at AM Expo, the trade fair for additive manufacturing. "Trade fairs such as the Swiss Plastics Expo and AM Expo provide an excellent platform for presenting our services. We can establish personal contact with many people involved in the development of companies, which is very valuable." By now we all know that this can lead to great things.